| Material: | |

|---|---|

| Color: | |

| MOQ: | |

| Packing: | |

| Availability: | |

| Quantity: | |

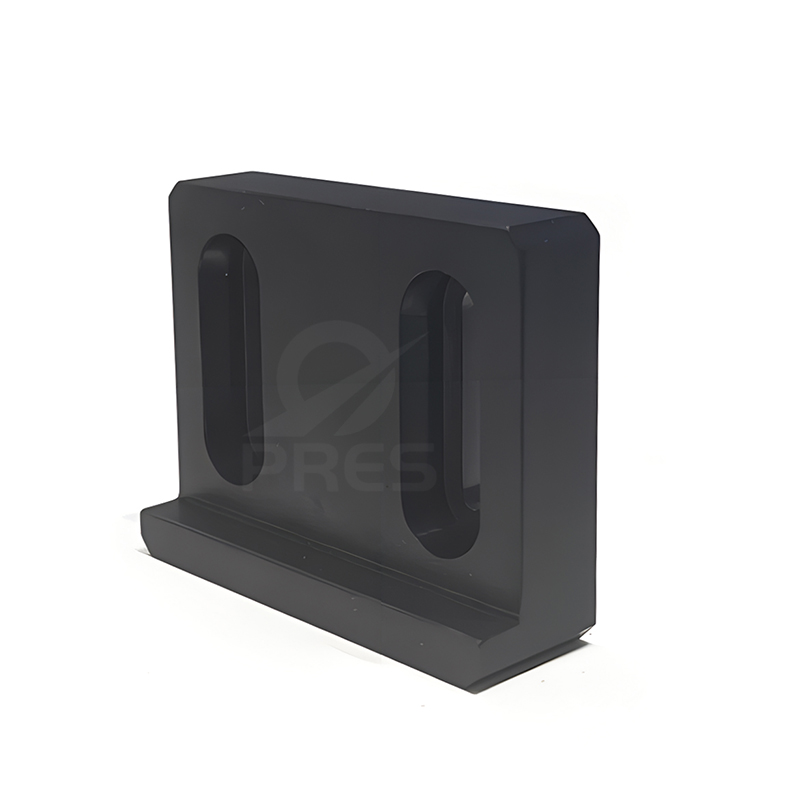

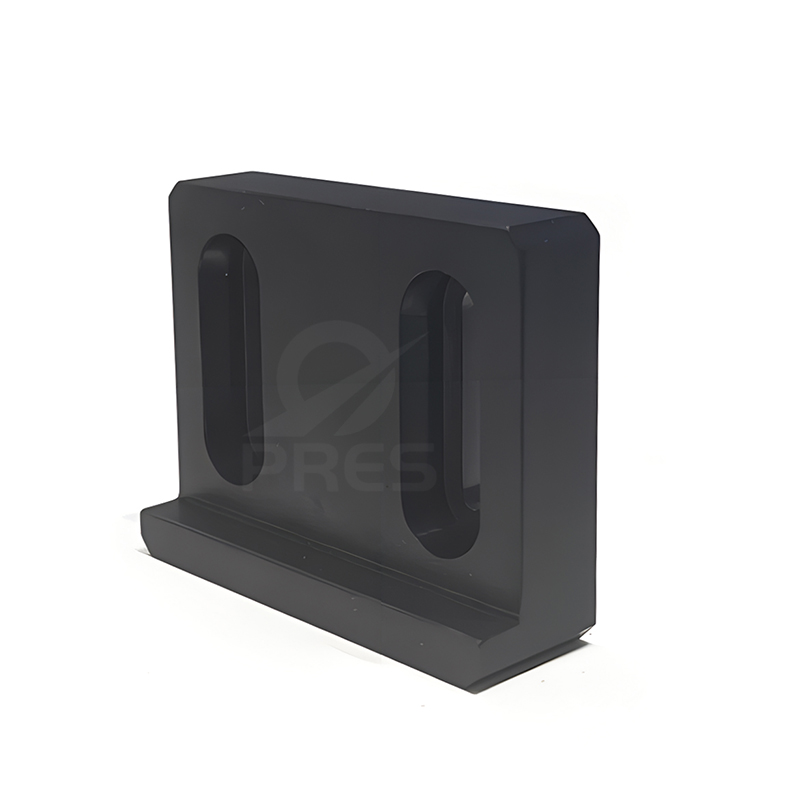

PPS-CF30

PRES

|

PPS GF40 Product Description

| High-temperature resistant | |

1.Glass transition temperature: 90°C 2.Heat distortion temperature: 260°C 3.Long-term using temperature: 200-240°C 4.Short-term using temperature: 260°C | ||

| Anti-static performance | |

The resistance of anti-static PPS is 106-9,The resistance remains stable in high-temperature and humid environments | ||

| Corrosion resistance | |

| It remains stable in most inorganic acids, bases and salts,The corrosion resistance is close to PTFE | ||

| hydrolysis resistanc | |

1.It can work for a long time in 120°C steam , and mechanical properties remain at 70% 2.Withstand 1000℃ steam cycle disinfection 3.After aging in high-pressure steam at 232℃ for 5,000 hours, it still maintains a mechanical strength> 50% | ||

|ESD PPS Application

By forming a conductive network on the material surface through conductive fillers, static charges are rapidly released, and the surface resistance is significantly reduced, effectively preventing the accumulation and discharge of static electricity

The anti-static performance remains stable in high-temperature and high-humidity environments and is not easily affected by changes in environmental temperature and humidity

Carbon fiber reinforcement further enhances the strength, wear resistance and impact resistance of PPS materials (such as load-bearing structural components)

Application scenarios:

Electronic component manufacturing, semiconductor equipment, explosion-proof equipment (such as coal mine and oilfield environments)

ESD PPS Shell

ESD PPS Pallet

ESD PPS IC tray

Glass fiber reinforced PPS

10% Glass fiber reinforced PPS

20% Glass fiber reinforced PPS

30% Glass fiber reinforced PPS

40% Glass fiber reinforced PPS

50% Glass fiber reinforced PPS

60% Glass fiber reinforced PPS

Read more

Coffe Color PPS

Coffee-colored PPS has a good appearance and has many application. This is a colored PPS pellets in stock.

And we have small quantity red color,blue color instock.

Read more

Custom color PPS

We have rich experience in color matching and can precisely control the proportion of pigments. We can mix accurate colors according to color numbers or samples in a relatively short time.

Read more

|Shipping & Payment

We can accept US dollars, rubles, and Chinese yuan

We can ship by sea,by air and express.

UPS

DHL

FEDEX

|

Certifications

|

Data Sheet

| Test Item | Test Method | Conditions | Units | Test Data |

| Mechanical Data | ||||

| Tensile Strength | ISO 527 | Yield, 23℃ | MPa | 160 |

| Tensile Elongation | ISO 527 | Break, 23℃ | % | 45 |

| Flexural Strength | ISO 178 | Yield,23℃ | MPa | 275 |

| Flexural Modulus | ISO 178 | 23℃ | GPa | 23 |

| Charpy Impact Strength | ISO 179/1eA | Notched | kJ/m2 | 30 |

| ISO 179/1U | Unnotched | kJ/m2 | 8.5 | |

| Mould Shrinkage | ISO 294-4 | Along Flow | % | 1 |

| Across Flow | % | 1.3 | ||

| Thermal Data | ||||

| Melting Point | ISO 11357 | - | ℃ | 283 |

| Flame retardancy | UL-94 | - | - | V0 |

| Heat DeflectionTemperature | ℃ | 260 | ||

| Injection molding conditions | ||||

| Drying temperature | ℃ | 130-150 | ||

| Drying time | Hrs | 3-4 | ||

| Cylinder temperature | ℃ | 290-320 | ||

| Nozzle temperature | ℃ | 300-320 | ||

| Mold temperature | ℃ | 120-150 | ||

| Injection pressure | MPa | 80-150 | ||

| Back pressure | MPa | 30-70 | ||

|

Testing Quality

We will test the performance of PPS material every batch,test including:

Flow rate

Tensile strength

Bending strength

Fracture elongation, etc

Hot Tags: Carbon Fiber Reinforced ESD PPS, Carbon Fiber Reinforced PPS, ESD PPS, High-Temperature Resistant Plastic, China, Low price, Customized, manufacturing company, manufacturer, factory, supplier, made in China, in stock

|

PPS GF40 Product Description

| High-temperature resistant | |

1.Glass transition temperature: 90°C 2.Heat distortion temperature: 260°C 3.Long-term using temperature: 200-240°C 4.Short-term using temperature: 260°C | ||

| Anti-static performance | |

The resistance of anti-static PPS is 106-9,The resistance remains stable in high-temperature and humid environments | ||

| Corrosion resistance | |

| It remains stable in most inorganic acids, bases and salts,The corrosion resistance is close to PTFE | ||

| hydrolysis resistanc | |

1.It can work for a long time in 120°C steam , and mechanical properties remain at 70% 2.Withstand 1000℃ steam cycle disinfection 3.After aging in high-pressure steam at 232℃ for 5,000 hours, it still maintains a mechanical strength> 50% | ||

|ESD PPS Application

By forming a conductive network on the material surface through conductive fillers, static charges are rapidly released, and the surface resistance is significantly reduced, effectively preventing the accumulation and discharge of static electricity

The anti-static performance remains stable in high-temperature and high-humidity environments and is not easily affected by changes in environmental temperature and humidity

Carbon fiber reinforcement further enhances the strength, wear resistance and impact resistance of PPS materials (such as load-bearing structural components)

Application scenarios:

Electronic component manufacturing, semiconductor equipment, explosion-proof equipment (such as coal mine and oilfield environments)

ESD PPS Shell

ESD PPS Pallet

ESD PPS IC tray

Glass fiber reinforced PPS

10% Glass fiber reinforced PPS

20% Glass fiber reinforced PPS

30% Glass fiber reinforced PPS

40% Glass fiber reinforced PPS

50% Glass fiber reinforced PPS

60% Glass fiber reinforced PPS

Read more

Coffe Color PPS

Coffee-colored PPS has a good appearance and has many application. This is a colored PPS pellets in stock.

And we have small quantity red color,blue color instock.

Read more

Custom color PPS

We have rich experience in color matching and can precisely control the proportion of pigments. We can mix accurate colors according to color numbers or samples in a relatively short time.

Read more

|Shipping & Payment

We can accept US dollars, rubles, and Chinese yuan

We can ship by sea,by air and express.

UPS

DHL

FEDEX

|

Certifications

|

Data Sheet

| Test Item | Test Method | Conditions | Units | Test Data |

| Mechanical Data | ||||

| Tensile Strength | ISO 527 | Yield, 23℃ | MPa | 160 |

| Tensile Elongation | ISO 527 | Break, 23℃ | % | 45 |

| Flexural Strength | ISO 178 | Yield,23℃ | MPa | 275 |

| Flexural Modulus | ISO 178 | 23℃ | GPa | 23 |

| Charpy Impact Strength | ISO 179/1eA | Notched | kJ/m2 | 30 |

| ISO 179/1U | Unnotched | kJ/m2 | 8.5 | |

| Mould Shrinkage | ISO 294-4 | Along Flow | % | 1 |

| Across Flow | % | 1.3 | ||

| Thermal Data | ||||

| Melting Point | ISO 11357 | - | ℃ | 283 |

| Flame retardancy | UL-94 | - | - | V0 |

| Heat DeflectionTemperature | ℃ | 260 | ||

| Injection molding conditions | ||||

| Drying temperature | ℃ | 130-150 | ||

| Drying time | Hrs | 3-4 | ||

| Cylinder temperature | ℃ | 290-320 | ||

| Nozzle temperature | ℃ | 300-320 | ||

| Mold temperature | ℃ | 120-150 | ||

| Injection pressure | MPa | 80-150 | ||

| Back pressure | MPa | 30-70 | ||

|

Testing Quality

We will test the performance of PPS material every batch,test including:

Flow rate

Tensile strength

Bending strength

Fracture elongation, etc

Hot Tags: Carbon Fiber Reinforced ESD PPS, Carbon Fiber Reinforced PPS, ESD PPS, High-Temperature Resistant Plastic, China, Low price, Customized, manufacturing company, manufacturer, factory, supplier, made in China, in stock