As a leading PPS Material Manufacturer, we specialize in delivering high-quality polyphenylene sulfide (PPS) materials that cater to a wide range of industries. Leveraging our extensive experience, advanced production facilities, and rigorous quality control systems, our company ensures that every PPS product we supply meets stringent performance requirements. From raw pellets to finished components, our offerings as a PPS Material Manufacturer are designed for reliability, durability, and versatility.

Our role as a PPS Material Manufacturer includes providing multiple grades and forms of PPS to meet diverse application needs. These categories include:

Natural PPS offers outstanding chemical resistance, excellent dimensional stability, and high thermal performance. As a PPS Material Manufacturer, we supply natural PPS in pellet or granule form, suitable for injection molding, extrusion, and other processing techniques. This grade is ideal for applications that require the inherent properties of PPS without additional reinforcement.

Glass-fiber reinforced PPS provides enhanced mechanical strength, rigidity, and wear resistance while retaining the core benefits of PPS. Our portfolio as a PPS Material Manufacturer includes 30%-40% glass fiber grades suitable for structural components, bearings, and high-stress applications.

For applications demanding superior strength, reduced friction, or improved thermal stability, we offer carbon-fiber and mineral-filled PPS compounds. These advanced materials, provided by our company as a PPS Material Manufacturer, are ideal for industrial machinery parts, automotive components, and high-precision applications.

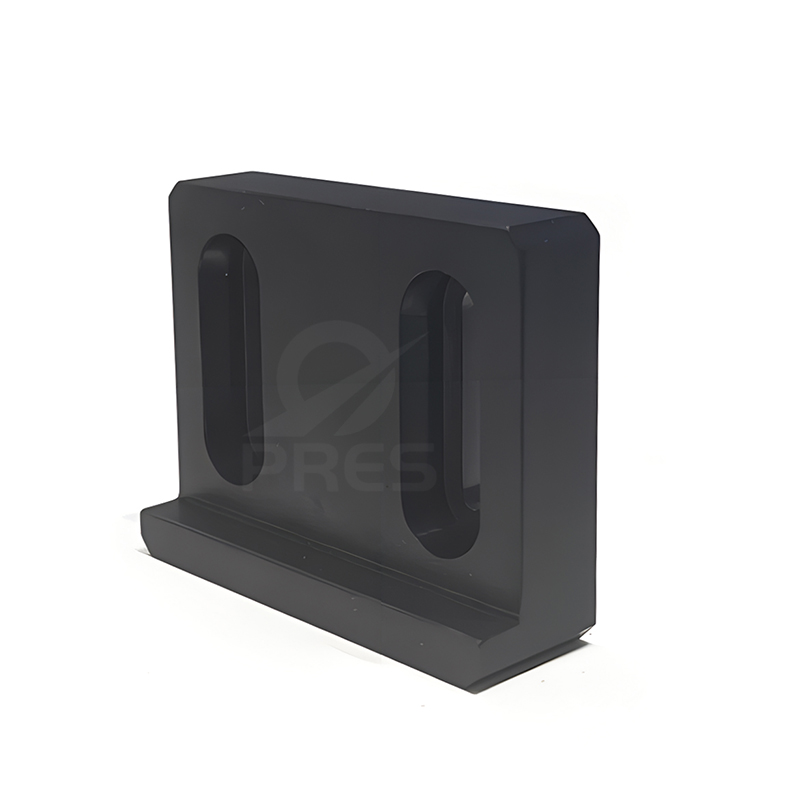

Beyond raw materials, we provide PPS in plates, rods, tubes, and customized machined parts. As a PPS Material Manufacturer, our comprehensive product line enables customers to prototype, machine, or directly integrate components into their products, reducing lead times and simplifying supply chains.

Our products as a PPS Material Manufacturer are used across a wide spectrum of industries:

PPS materials excel in under-hood applications, fuel systems, throttle bodies, and electrical connectors. Reinforced PPS grades provide strength and creep resistance, allowing OEMs to replace metals and reduce weight without compromising performance.

Flame-retardant and dimensionally stable, PPS is widely used in connectors, insulators, switch housings, and high-temperature electronic components. Our company, as a PPS Material Manufacturer, ensures that these grades meet the strictest insulation and heat tolerance requirements.

In environments exposed to aggressive chemicals, PPS materials offer unmatched resistance and longevity. Our PPS products serve pumps, valves, bushings, and other critical components, providing reliable performance where conventional plastics fail.

Reinforced PPS materials are ideal for gears, sliding elements, bearings, and wear-resistant parts. As a PPS Material Manufacturer, we provide materials that reduce maintenance, extend service life, and maintain dimensional accuracy in demanding industrial operations.

PPS is also used in lighting reflectors, appliance components, semiconductor equipment, and more. Our range of PPS sheets, rods, and tubes allows for rapid prototyping, machining, and production of precision parts, highlighting our versatility as a PPS Material Manufacturer.

PPS materials can operate continuously at elevated temperatures while maintaining dimensional stability. As a PPS Material Manufacturer, we emphasize this property as essential for demanding applications in automotive, chemical, and electronic sectors.

Reinforced PPS grades offer superior stiffness, wear resistance, and creep performance. Our role as a PPS Material Manufacturer ensures that clients receive materials capable of replacing metals and more expensive polymers while delivering reliable results.

Low moisture absorption and thermal expansion make PPS ideal for tight-tolerance parts. As a PPS Material Manufacturer, we support customers requiring precision machining and high-quality injection-molded components.

PPS materials inherently provide flame resistance and dielectric strength. Our PPS products meet demanding safety standards, making them suitable for electronics and high-temperature applications.

By replacing metals and ultra-high-performance polymers, PPS offers cost efficiency and weight reduction. As a PPS Material Manufacturer, we help clients optimize both performance and budget considerations.

Long service life, reduced maintenance, and recyclability make PPS materials environmentally friendly. As a PPS Material Manufacturer, we prioritize sustainable practices in production and material selection, supporting circular economy initiatives.

Advanced extrusion, molding, and testing equipment ensure consistent product quality. Our systems as a PPS Material Manufacturer provide customers with high reliability, meeting rigorous industrial and regulatory standards.

We provide tailored PPS compounds, fillers, and processed forms to meet specific application needs. Partnering with us as a PPS Material Manufacturer means flexible solutions, technical support, and faster time-to-market.

* Comprehensive Product Range: From raw PPS pellets to finished machined parts.

* Advanced Technical Expertise: Custom compounds and reinforced grades.

* Industry Leadership: Trusted by automotive, electronics, chemical, and industrial clients.

* Sustainability Focus: Materials with long service life and recycling potential.

* Reliable Supply Chain: Consistent quality and global logistics.

Q1: What are the main types of PPS materials?

A1: The primary types include natural (unfilled) PPS, glass-fiber reinforced PPS, carbon-fiber or mineral-filled PPS, and PPS sheets/rods/tubes for machining. Each type offers specific benefits for different applications.

Q2: How does reinforced PPS differ from natural PPS?

A2: Reinforced PPS includes fillers like glass or carbon fibers to improve strength, stiffness, wear resistance, and dimensional stability, while natural PPS provides standard chemical and thermal resistance without reinforcement.

Q3: In which industries is PPS most commonly used?

A3: PPS is used in automotive, electronics, chemical processing, industrial machinery, and specialty applications where high temperature, chemical resistance, and dimensional stability are required.

Q4: Are PPS materials environmentally sustainable?

A4: Yes. PPS materials have long service life, are often recyclable, and reduce replacement frequency, contributing to lower environmental impact.

Q5: How do I select the right PPS grade for my application?

A5: Selection depends on operating temperature, chemical exposure, mechanical load, electrical requirements, and desired precision. As a PPS Material Manufacturer, we guide clients in choosing the optimal grade.